- Vue d’ensemble

- Membres

- PRESENTATION 1er Message

- Diagnostics, recherche de pannes

- Vos tutos

- PRÉPARATION RACING

- ASTUCES & GADGETS

- Documentations techniques

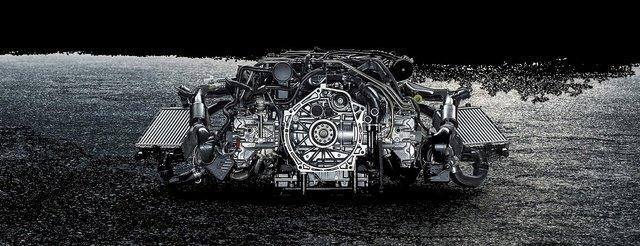

- MOTEUR

- CARROSSERIE

- CHÂSSIS

- ELECTRICITE

- HABITACLE

- INJECTION CARBURANT

- ECHAPPEMENT

- BOÎTE VT

- REFROIDISSEMENT

- FREINS

- PCM-GPS-CDR

- CAPOTE - TOIT OUVRANT

- FILTRE AIR / BOITIER FILTRE A AIR / DÉBITMÈTRE

- IMS

- LE GARAGE

- VENTE DE PIÈCES PORSCHE

- Photos

- RECHERCHE PIÈCE

- VENTE PORSCHE

- Les bonnes adresses

- NEWS- Revue de presse

- PORSCHE 992

- PORSCHE 991

- PORSCHE 997

- PORSCHE 996

- PORSCHE Cayman 718

- PORSCHE Cayman 981

- PORSCHE Cayman 987

- PORSCHE Boxster 718

- PORSCHE Boxster 981

- PORSCHE Boxster 987

- PORSCHE Boxster 986